What Is a PCB? The Ultimate Guide to Printed Circuit Boards

Printed Circuit Boards (PCBs) are foundational elements of modern electronics. They facilitate essential electrical connections within devices. In this article we will explore the multifaceted world of PCBs, exploring their historical evolution, structural composition, types, manufacturing techniques, and the applications that affirm their relevance in today's rapidly advancing technological landscape.

What is a PCB? Simple Definition

At its simplest, a Printed Circuit Board (PCB) is a flat board made of insulating material that contains conductive pathways etched from copper sheets. These pathways connect various electrical components, enabling them to communicate and function together in electronic devices.

What is a PCB in Engineering?

In engineering, a PCB is an essential component that supports and connects electronic parts compactly. Engineers use PCBs to design devices that meet specific performance, reliability, and size requirements. These printed circuit boards can range from simple single-sided designs to complex multi-layer structures for advanced technology.

A Brief History of PCBs

Early PCBs

The history of PCBs dates back to the early 20th century. The first patent for a printed circuit board design was filed by Paul Eisler in 1936, but they gained significant traction during World War II due to their use in military devices. As the need for compact and reliable electronic components increased, PCBs started to replace traditional point-to-point wiring. This shift paved the way for modern electronics.

Recent Advances

Since those early days, the evolution of PCBs has continued at a rapid pace. Technological advancements have resulted in the creation of High-Density Interconnect (HDI) boards and embedded PCBs. They have also facilitated the integration of surface-mount technology (SMT). Modern designs emphasize miniaturization, enabling the production of advanced consumer electronics, medical devices, and communications technology.

Composition of PCBs

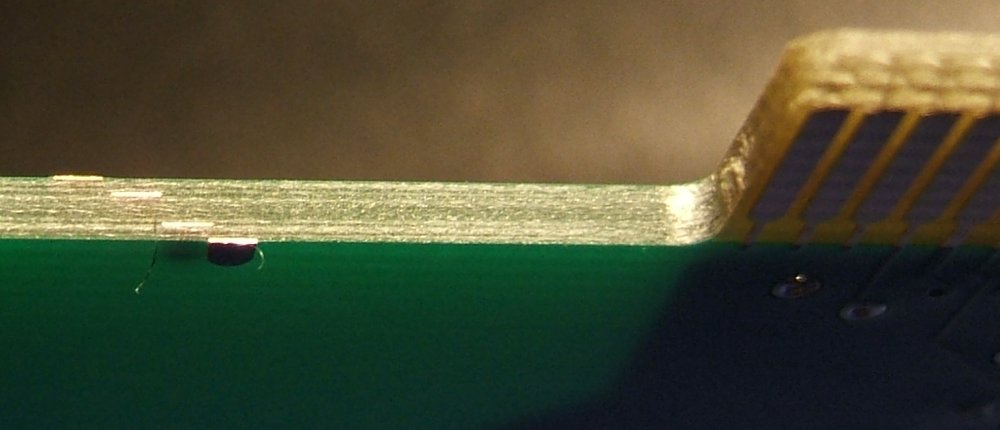

Layers

Typically, PCBs consist of several layers, each serving a specific function:

- Substrate Layer: This insulating layer is usually made from a substrate material - fiberglass resin known as FR-4, It gives structure to the PCB.

- Copper Layer: The conductive layer is usually made of copper. It carries electrical signals between components and can be present on one or both sides of the substrate.

- Solder Mask: This protective coating prevents solder from connecting unwanted areas during PCB assembly. It also provides insulation and protects against damage.

- Silkscreen Layer: This layer displays text and symbols for component placement. It helps in identification during assembly and repair.

Component Mounting

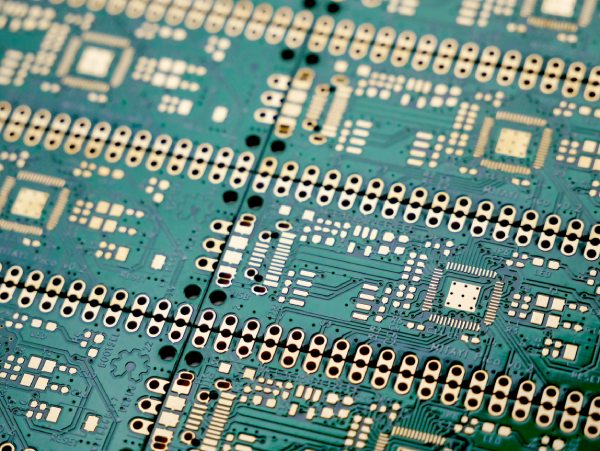

PCBs provide mechanical support for mounting various electronic components, such as resistors, capacitors, and integrated circuits (ICs). PCB components can be mounted either through-hole (inserting leads through the board) or surface-mount (placing components directly onto the board surface).

Electrical Properties

The electrical performance of a PCB is influenced by several critical factors, including its layer stack, trace width, dielectric material, and more. Among these, controlled impedance is vital for maintaining signal integrity, particularly in high-speed applications where variations can lead to data loss or distortion.

Additionally, the capacitance and inductance characteristics of the PCB design significantly impact signal behavior. Properly addressing these properties is essential for ensuring reliable and efficient performance in advanced electronic systems.

Materials Used in PCB Construction

Key Materials in PCB Construction

The construction of Printed Circuit Boards (PCBs) relies on a careful selection of materials, each playing a distinct role in the board's performance and functionality. The three primary materials used in PCB construction are copper, resin, and glass.

- Copper: This is the primary conductive material, essential for creating the electrical pathways on the PCB. Copper remains the predominant conductive material in PCB construction due to its superior conductivity, which is approximately 58% of the International Annealed Copper Standard (IACS). Due to its excellent conductivity, copper is utilized in various forms, including thin copper foils and thicker copper layers, allowing for efficient current flow and signal transmission. It is often etched onto the PCB to form intricate trace designs that connect different components.

- Resin: Serving as a binding agent, resin provides electrical insulation and structural cohesion to the PCB. It encapsulates the glass fabric and integrates with copper layers, ensuring durability and maintaining the integrity of electrical signals. Different types of resin offer varying thermal and dielectric properties, which are crucial for the board’s performance, particularly in high-frequency applications.

- Glass: Typically used as a reinforcement material, glass fabric enhances the mechanical strength and stability of the PCB. It contributes to the overall rigidity and thermal resistance of the board while preventing warping or bending under extreme conditions. Glass does not conduct electricity, making it an ideal choice for maintaining insulation between conductive paths.

Together, these materials form the backbone of reliable and efficient PCB construction, enabling the design and manufacturing of modern electronic devices that require robust performance and durability.

PCB Manufacturing Process

Understanding the manufacturing processes of printed circuit boards (PCBs) is crucial for engineers and designers alike. Here, we outline the key steps involved in PCB fabrication:

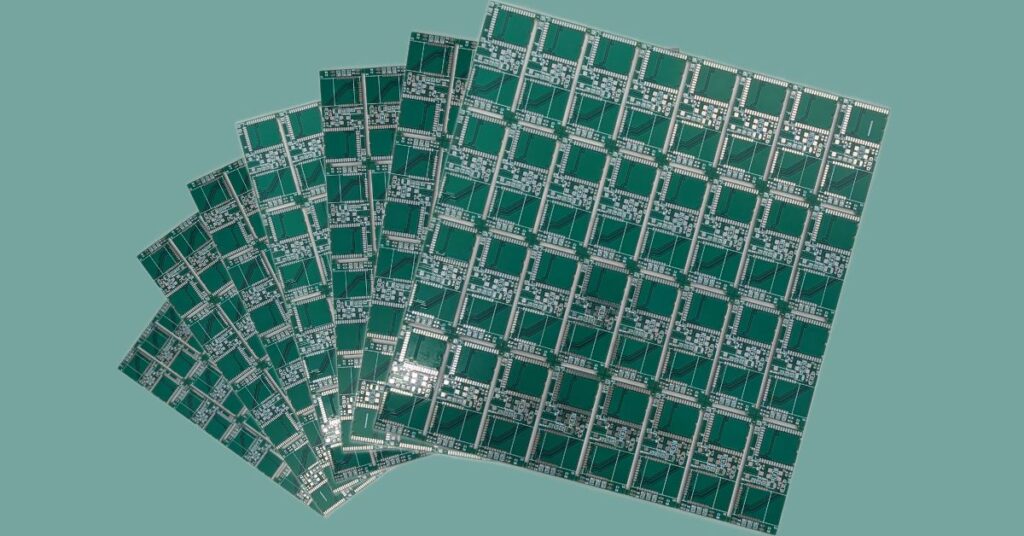

Panelization and Depaneling

- Panelization: This initial step involves designing multiple PCBs on a single panel to enhance manufacturing efficiency.

- Depaneling: Once PCB assembly is complete, this process involves meticulously cutting the individual boards from the panel.

Copper Patterning and Etching

- Copper Patterning: First, a layer of photoresist is carefully applied to the copper surface. Then, ultraviolet light exposes the areas that outline the desired circuitry patterns.

- Etching: In this essential step, chemicals are used to selectively remove the exposed copper. This process leaves behind the intricate traces that create the electrical connections.

Lamination

During the lamination stage, multiple layers of material are bonded together under controlled heat and pressure. This critical process ensures that all layers are securely attached, creating a solid, cohesive structure that supports the overall integrity of the PCB.

Drilling and Vias

- Drilling: Precision drilling is performed to create holes that accommodate the leads of various components and to establish vias—vertical connections between different layers of the PCB.

- Vias: These small, plated holes facilitate the electrical connection between multiple layers, enabling complex circuit designs and compact configurations.

Plating and Coating

- Plating: To enhance solderability and protect the underlying copper, thin layers of metals such as gold, silver, or tin are applied.

- Solder Resist Application: A solder mask is carefully applied to safeguard non-solderable areas of the board.

Bare-Board Testing

Following the manufacturing process, bare-board testing is conducted to verify that all electrical connections meet specified performance standards. This essential quality control step occurs prior to component assembly, ensuring that any potential issues are identified and addressed early in the production cycle.

PCB Assembly

The PCB assembly (PCBA) process is a critical step in the manufacturing of electronic devices and involves several stages to ensure the correct placement and soldering of components on the PCB. The process can be divided into several key steps, each contributing to the overall quality and functionality of the final product.

Component Sourcing

Before any assembly can occur, the necessary electronic components need to be sourced. This includes resistors, capacitors, integrated circuits (ICs), and other hardware. Component sourcing can involve:

- Identifying specifications: Ensuring components meet the required standards for voltage, tolerance, size, etc.

- Supplier selection: Choosing reliable suppliers to ensure quality and timely delivery of components.

- Inventory management: Keeping track of component stock to avoid shortages or delays.

PCB Fabrication

Before assembly, the PCB itself must be fabricated. This involves:

- PCB Design: Creating a PCB layout using software tools (like Altium Designer, Eagle, or KiCad) where the schematic is converted into a physical layout.x

- PCB Manufacturing: The fabrication of PCBs typically includes etching copper layers, drilling holes for vias, and preparing the surface for soldering.

- PCB Testing: Quality assurance through visual inspection and electrical testing to catch faults early in the manufacturing process.

Surface-Mount Technology Assembly

Surface-Mount Technology (SMT) is one of the most common methods for assembling electronic components on PCBs:

- Solder Paste Application: A stencil is used to apply solder paste to specific areas of the PCB corresponding to the pads where components will be placed.

- Component Placement: Automated machines (pick-and-place machines) position components precisely onto the solder paste.

- Reflow Soldering: The PCB then goes through a reflow oven where the solder paste melts and solidifies, effectively soldering the components onto the board.

Through-Hole Technology (THT) Assembly

While SMT has many advantages, through-hole assembly is still used for certain components:

- Component Insertion: Components with leads are manually or automatically inserted into pre-drilled holes on the PCB.

- Soldering: This can be done through wave soldering or manual soldering. Wave soldering involves passing the PCB over a wave of molten solder, ensuring robust solder joints for through-hole components.

Inspection and Testing

Quality control is critical in printed circuit board assembly:

- Visual Inspection: Checking for misaligned components, solder bridges, PCB tombstoning and other visible defects.

- Automated Optical Inspection (AOI): Using machines to scan the PCB for defects.

- Functional Testing: Verifying the PCB operates as intended by simulating its operational environment and checking for electrical conformity.

Cleaning

After soldering, any flux residues or contaminants need to be cleaned off:

- Washing: Using ultrasonic cleaners or solvent cleaning methods to remove excess flux and contaminants from the PCB surfaces.

- Drying: Ensuring the PCB is thoroughly dried to prevent moisture-related issues.

Final Assembly and Packaging

Once assembled PCBs are tested, they may go through final printed circuit board assembly:

- Integration: PCBs are assembled into their respective enclosures or cases, connecting them with other hardware components (like connectors or interfaces).

- Final Testing: Conducting a final functional test to ensure everything works correctly in its operational environment before shipping.

- Packaging: Proper packaging for shipping, including anti-static materials and protective casing to prevent damage during transport.

Documentation and Compliance

Finally, it's essential to maintain thorough documentation and ensure compliance:

Documentation: Keeping records of the assembly process, testing results, and traceability for components to ensure quality and ease of future troubleshooting.

Quality Standards: Adhering to standards such as IPC-A-610 (Acceptability of Electronic Assemblies) and ISO certification.

Types of Printed Circuit Boards

Various types of PCBs serve different functions and applications:

1. Breakout Boards

Breakout boards are small PCBs designed to break out the pins of a larger IC or component, making them easier to work with in prototyping or testing scenarios.

2. Multiwire Boards

These boards are designed to handle multiple signal wires, allowing for connections to multiple components in a compact area, often used in complex systems.

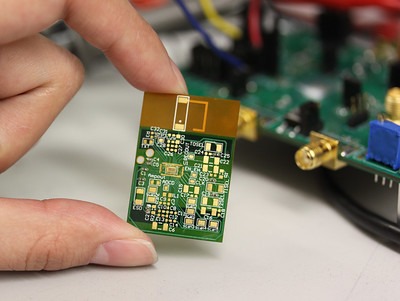

3. Rigid, Flexible, and Rigid-Flex PCBs

- Rigid PCB

Made from materials such as fiberglass and epoxy resin, these boards have a solid and inflexible structure, making them ideal for a variety of devices like computers, televisions, and industrial equipment. - Flexible PCB

Thin, lightweight boards constructed from materials like polyimide or polyester, allowing them to bend and conform to various shapes. They are ideal for wearable devices, including smartwatches and fitness trackers, promoting innovative design and ergonomics. - Rigid-Flex PCB

Hybrid boards that combine rigid and flexible sections for complex designs in limited spaces. Commonly used in smartphones, medical devices, and aerospace applications, they provide reliability and compactness for intricate layouts.

Applications of PCBs: What Are Printed Circuit Boards Used For?

Printed Circuit Boards are integral to the functionality and performance of nearly every electronic device in use today. Their versatility allows them to be deployed in a wide range of applications across different sectors. Here, we will further explore several key areas where PCBs play a vital role, highlighting their significance in modern technology.

Consumer Electronics

PCBs are omnipresent in consumer electronics, forming the backbone of devices such as smartphones, tablets, laptops, televisions, and gaming consoles. They underpin critical functions that contribute to the compactness and efficiency of today's gadgets, including:

- Power Distribution: Efficiently managing power supply to various components.

- Signal Processing: Facilitating communication between integrated circuits.

- Component Support: Providing structural integrity to House components in a compact design.

Recent advancements in PCB design—such as the shift towards thinner, multi-layer boards and the widespread adoption of surface-mount technology (SMT) - have driven significant improvements in both functionality and complexity. Notably, flexible PCBs are revolutionizing the consumer electronics landscape, empowering manufacturers to create slimmer, lighter devices with innovative form factors and enhanced usability.

Automotive Components

The automotive industry has rapidly embraced advanced electronics for improved vehicle safety, performance, and convenience. PCBs are crucial in various applications, including:

- Engine Control Units (ECUs): These boards manage engine performance and systems such as fuel injection and ignition timing.

- Infotainment Systems: PCBs are central to providing multimedia capabilities, navigation, and connectivity features in vehicles.

- Sensors and Safety Systems: PCBs are incorporated in systems like anti-lock braking systems (ABS), airbags, and advanced driver-assistance systems (ADAS) to enhance vehicle safety and automation.

- As electric vehicles (EVs) gain traction, the demand for sophisticated printed circuit board designs will increase, accommodating the extensive electronics required for electric drive systems, battery management, and autonomous driving technologies.

LED Technology

PCBs are essential in the realm of LED (Light Emitting Diode) technology, which has transformed lighting solutions for commercial and residential environments. Specially designed LED PCBs serve multiple purposes:

- Thermal Management: Efficient heat dissipation through the PCB helps maintain optimal LED performance and longevity.

- Compact Design: PCBs allow for intricate configurations, enabling the development of diverse lighting products.

- Integration with Control Systems: PCBs enable the incorporation of dimming features, color-changing capabilities, and smart controls, enhancing user experience and energy efficiency.

Aerospace Components

In the aerospace sector, PCBs are vital for ensuring the reliability and safety of electronic systems used in aircraft and spacecraft. They are found in:

- Avionics Systems: PCBs support navigation, communication, and flight control systems that are crucial for safe aircraft operation.

- Satellite Technology: Advanced PCBs are used in satellite systems, where they must withstand extreme conditions, such as temperature fluctuations and radiation.

- Monitoring and Control Systems: For real-time telemetry and diagnostics, PCBs are used to collect and process data from various sensors throughout an aircraft or spacecraft.

- The high-stakes nature of aerospace applications demands robust, high-reliability PCBs that can operate under challenging conditions for extended periods.

Medical Devices

The medical industry relies heavily on PCBs for their precision and reliability in critical applications. Examples include:

- Diagnostic Equipment: PCBs are used in machines like ultrasound devices, MRI scanners, and blood analyzers, where they support sophisticated sensors and data processors.

- Implantable Devices: Such as pacemakers, which require ultra-reliable PCBs capable of functioning in harsh biological environments.

- Wearable Health Monitors: Devices like fitness trackers and smartwatches integrate flexible PCBs to maximize comfort and functionality.

- The stringent regulatory framework governing medical devices necessitates high standards of quality and reliability in printed circuit board manufacturing, ensuring patient safety and effective operation.

Industrial Equipment

PCBs play a pivotal role in various industrial automation and control systems, enhancing efficiency and performance across multiple applications:

- Motor Control: PCBs regulate and control electric motors, ensuring precision and efficiency in manufacturing processes.

- Robotics: In industrial robots, PCBs orchestrate the functioning of motors, sensors, and communication systems, enabling complex movements and tasks.

- Power Management: PCBs are employed in power supply units to manage and distribute electrical power efficiently for operational stability.

- As industries transition towards automation and smart manufacturing, the reliance on advanced PCB will continue to grow.

Conclusion

Printed Circuit Boards are pivotal in the advancement of modern electronics, evolving from simple designs to sophisticated configurations capable of supporting complex, high-speed systems. Their composition, manufacturing processes, and versatility across applications illustrate the essential role they play in engineering and technology.

As industries continue to innovate, the importance of PCBs will remain paramount, driving the future of electronic design and fabrication. Understanding their intricacies not only aids engineers in creating better products but also enhances our comprehension of the technology that shapes our world today.